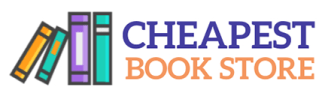

Reliability Engineering and the Application of CNC Machine Tools

$220.00 Original price was: $220.00.$38.00Current price is: $38.00.

Author: Yan Ran; Genbao Zhang

Publisher: Elsevier (S&T)

Print ISBN: 9780443340116

Delivery Time: Within 4 hours

Copyright: 2025

500 in stock

- Save up to 60% by choosing our eBook

- High-quality PDF Format

- Lifetime & Offline Access

Reliability Engineering and the Application of CNC Machine Tools

Reliability Engineering and the Application of CNC Machine Tools by Yan Ran and Genbao Zhang is an authoritative, practice-driven guide that brings reliability science straight to the shop floor. Ideal for engineers, maintenance managers, and technical students, this book distills complex theory into clear strategies for optimizing CNC machine performance and uptime.

Start with a compelling blend of real-world case studies and rigorous methodology that explains how to identify failure modes, quantify risk, and apply statistical reliability models specifically for CNC systems. The authors bridge the gap between design and operations, covering predictive maintenance, condition monitoring, root-cause analysis, and lifecycle planning—tools you can implement immediately in precision machining, automotive, aerospace, and mold-making environments.

What sets this work apart is its actionable focus: step-by-step procedures for fault diagnosis, reliability-centered maintenance plans tailored to CNC architectures, and guidance on integrating sensor data and industry-standard metrics to reduce downtime and cost. Practical charts, decision frameworks, and performance indicators make it easy for teams to prioritize interventions and measure improvements.

Whether you manage a single milling center or a distributed manufacturing line across global hubs like China, Europe, or North America, this book equips you to increase throughput, extend equipment life, and improve product quality. Clear, authoritative, and industry-relevant, it’s the essential resource for anyone committed to making CNC operations more predictable and profitable.

Add this indispensable manual to your technical library and transform how your shop approaches reliability and maintenance.

Note: eBooks do not include supplementary materials such as CDs, access codes, etc.

Related Books

Technology & Engineering

Technology & Engineering

Technology & Engineering

Fundamentals of Spacecraft Attitude Determination and Control – 1st Edition

Technology & Engineering

Technology & Engineering

Technology & Engineering

Technology & Engineering

Critical Regimes of Two-Phase Flows with a Polydisperse Solid Phase

Technology & Engineering